Our Lean Journey

What is lean?

Lean is a culture of continuous improvement. The method of building this culture is getting excited about a process of continuously making small improvements that add up to major savings over time. Lean is simple and can be done by anyone. It is not about gaining profits, but is all about eliminating waste and adding value to products and processes. A company cannot successfully implement Lean unless it realizes it must implement a company wide culture of improvement that betters the lives of the employees, adds value to the customer, and aggressively eliminates waste.

Three Pillars of Lean

Seeing Waste

Continuously improve everything and everybody, every day

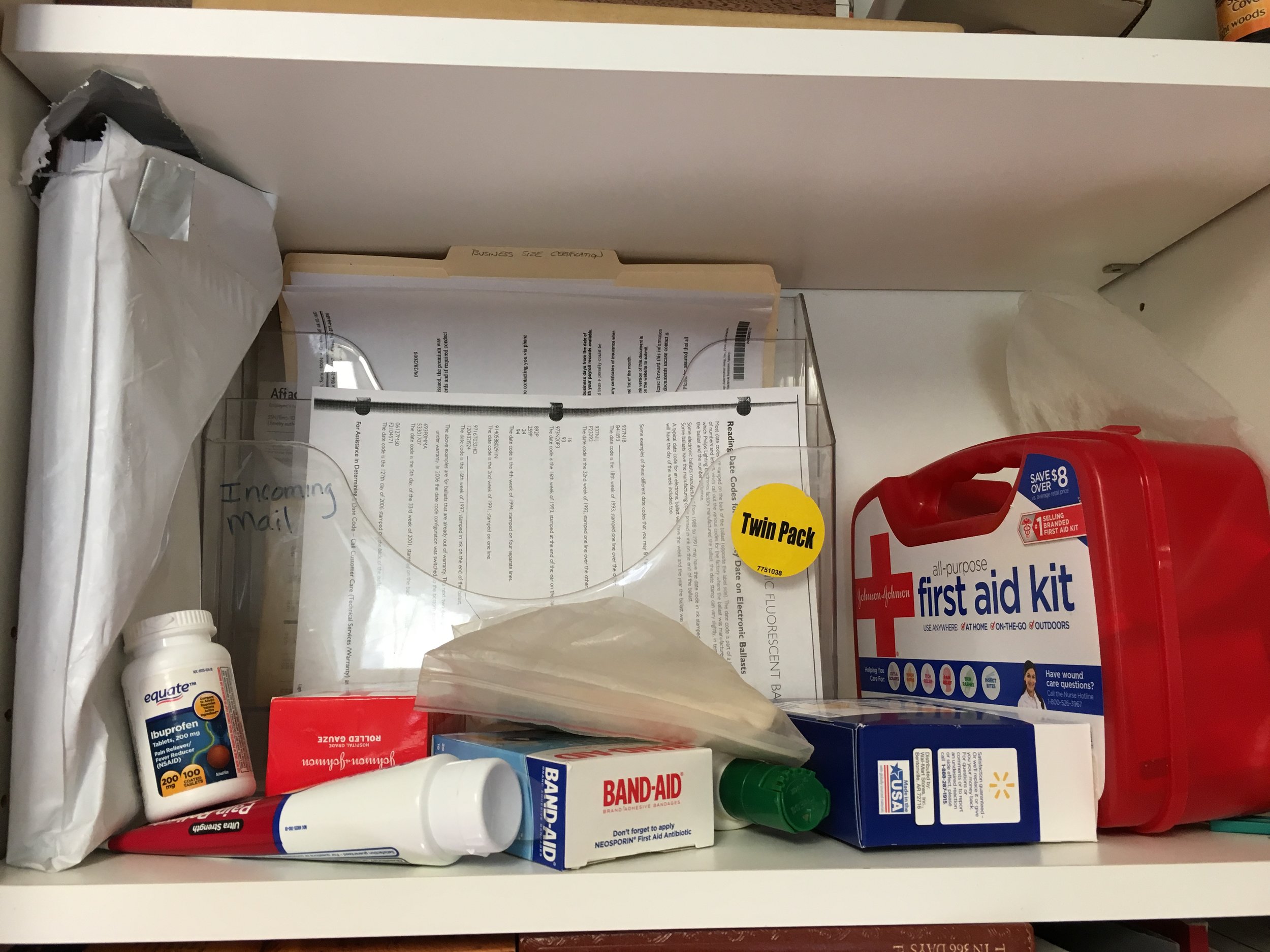

Before and after videos/photos

The 8 Wastes

In order to see waste we must learn to recognize it. A tool for recognizing waste is learning the 8 wastes. Waste in manufacturing, and life in general can be broken down into 8 categories as can be seen below.

Each waste is interconnected with the others, but the key to stopping the cycle of waste is utilizing employee genius.

This detective emoji is posted all over our shop reminding us to seek out the culprits that want to steal our productivity!

Continuous Improvement

In order to provide maximum value to customers, every member of the team must give maximum effort. Each employee has hidden genius and a unique perspective that should be used to solve problems. Each day, every employee makes one small improvement with the goal of trimming at least 2 seconds of waste from a process. These improvements are not to be orchestrated by managers, but stem directly from the ideas of employees.

Before and After Documentation

The key to getting the process of improvement to stick is taking before and after videos of all the improvements made. It is easy for a company to forget how far they have come and get discouraged. Making vivid history of the journey helps to validate employees and motivate a company to continue the constant process of improving. The final part of documentation is sharing the journey. Lean is a culture of improvement and encouraging others. So the final step is sharing and helping to grow the culture of continous improvement!

Looking at all the waste and then seeing it disappear is like a breath of fresh air, which is why it is important to document the change and use it to motivate ourselves to continually improve.